Drawing from the tradition of glass-makers

Stained glass has a history that spans more than a thousand years. In this article we reflects on the history of this product. Like most art forms, stained glass require particular pattern to arrive at its artistic form. Having potency to reflect and change light, art glass quickly became understood as the important mood and ambience tool. Many historians attribute revival of European cultures with the use of colored glass for the spiritual gatherings.

Around 1450’s new stain called Cousin’s rose was implemented to create flesh tones. From 1600s onwards, many glass designs were utilizing stains that were made from crushed particles. In the 1700s, stained glass evolved from cutting glass pieces to directly painting on the panels that were like tiles. Special paints containing Arabic gum, crushed glass, and copper filings mixed with vinegar and wine are used to color the surfaces. With time newer stains got introduced. For instance, yellow hue would be produced from silver nitrate. It would be first turned into a paint and then fired. Our approach is to combine carving by sandblasting deeply into the glass and then applying design and coloring over the created outlines in the texture. Artisans find that as the best way to create design so dimensional and textured. All designs are handcrafted and customizable to sizes as needed.

Glass sketches and design layouts

Starting with the initial phase of creative process exact dimensions are required. Sometimes, when the opening is odd shaped it is better to create a template out of paper or wood. Next, a pattern or design concept is decided upon. Before moving into production a black and white outlined sketch is offered to the homeowner. Small sample can be manufactured to combine the textures together and verify the appearance of the finished window, mural, partition, or stained glass front door.

Some company will provide you a pre-production sketch for all the design layouts before sending it for production.

Traditional designs might include narrative or depict a story. A figurative stained glass wall art may depict saints and other religious figures. Often mottoes and scriptural texts are also included. Contemporary designs are quite different and include lots of themes and patterns from world culture.

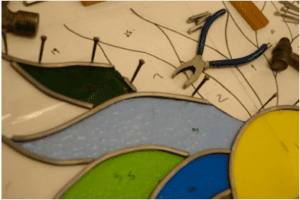

For generations craftsman around the world mastered the science of working with glass. The craft of staining was very complicated. For each opening a detailed preview sketch was drawn. Sketch was subdivided into patchworks, working as exact reference for each segment. Then, lead framing positioning would be determined. All cut out pieces will be assembled into one unit for final installation. In the contemporary industry we see tendency to use alternative of carved glass in many applications.There we do not need to create many pieces and try to hold them together by a frame, rather we work with one piece, that we carve into and create textures. With traditional glass-work colored pieces are carefully selected and matched to the sketch. A grozing tool often used to work on the sides of the product creating edges.

Mounting and Assembly of glass paneling

When creating traditional stained glass, after cutting the panel individual pieces are put together into H-sectioned lead slots. The joints are then soldered to prevent rattling. An oily cement is then applied between each lead slot or came to make the window weatherproof. Modern artists when creating stained glass for sale utilize copper instead of lead.

Selection and Painting

Palace of Glass style of stained glass is produced out of one flat piece of glass that is carved and stained by enameled paints. Custom developed process allows our artisans to combine carving of the outlines of images with the coloring afterwards. As a result textures of the images are not merely drawings on the glass but dimensional textures.

Details such as figures and background textures could be applied later by enamel paints and then heat treated to absorb the coloring into the textured surface of the glass.

In our company we do not use any lead related products, all our enameled based paints are environmentally friendly. We also do not combine product from different pieces, but use one solid panel on which we then carve different designs and elements. That makes this architectural product much stronger, safer, and better looking. We think this is a better alternative to many glass needs.

We will be happy to customize any existing design that you see in our catalog; check with us for stained glass panels.

Contact for a free consultation!